Factory Construction

We offer comprehensive support for factory construction, and production and auxiliary facilities throughout EPCC services, placing an emphasis on factory production efficiency.

Our factory construction projects are designed, taking production facilities into consideration in order to build factories that best match our clients' needs.

We offer full support for all aspects of a project, ranging from the design and erection of factory buildings and manufacturing facilities, power receiving and transforming facilities, water facilities, air-conditioning facilities, lighting facilities, entry/exit control, and security equipment such as surveillance cameras.

We also meet a wide range of requirements, such as replacing existing factories and enhancing earthquake safety. For example, we offer one-stop services for transferring production facilities overseas, including dismantling and packaging domestic facilities, taking care of all transportation and import procedures, constructing factories overseas, and restoring all existing facilities to working order.

- Key Points

-

- Our systematic construction method helps cut costs, reduce delivery periods, and provide high quality.

- We offer comprehensive support for the construction of buildings and production facilities, and the installation of power receiving and transforming facilities and other types of auxiliary equipment.

- We offer one-stop support for the dismantling, exporting/import procedures, and reassembly of existing facilities in transferring a factory overseas.

- Major Projects Completed

-

- Sowa Sangyo Co., Ltd.: Construction of a new factory [Saitama]

- TS TECH Co., Ltd.: Construction of a new seat factory and a parts control center (PCC) storage [Saitama]

- TIGERPOLY (THAILAND) LTD.: Construction of an auto parts production plant [Thailand]

- Nabari Factory of Marubishi Oil Chemical Co., Ltd.: Construction of a new wet grinding mill factory [Mie]

- TS Tech Co., Ltd. : Construction of a new building in the Hamamatsu Plant [Shizuoka]

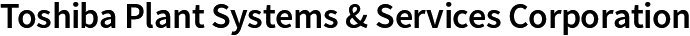

Manufacturing Facilities

Total support for production facilities, including chemical, pharmaceutical, food, and equipment assembly plants

In order to help optimize an entire production facility with regard to circulation planning and zoning for segregating between workers and parts as well as production management systems, we offer comprehensive engineering services, ranging from the survey and planning stages to the design and implementation stages. This is to efficiently realize a safe and comfortable facility.

In order to fully satisfy client requirements, we also offer one-stop services, encompassing cleanrooms and transportation, packaging and storage facilities, as well as security systems in the vicinity of production facilities.

- Key Points

-

- A 4D simulation process flow has been added to our 3D design data that consist of construction material quantity management, schedule planning, and personnel planning.

- We offer safe and comfortable production facilities without waste through total engineering.

- Major Projects Completed

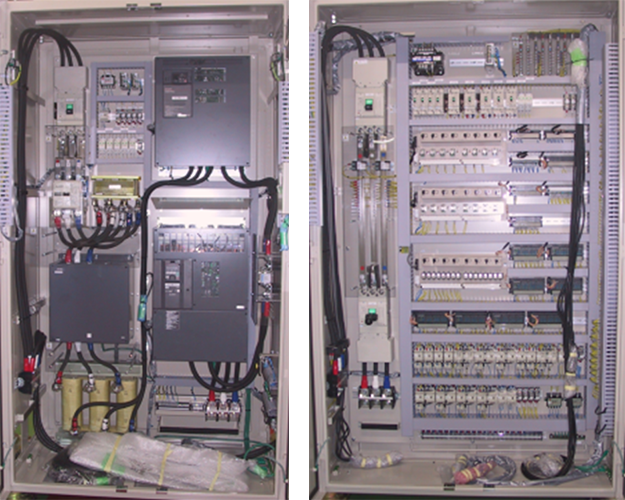

Power Receiving and Transforming Facilities

EPCC services for ultrahigh-voltage transforming and substation facilities using equipment from diverse manufacturers

We offer systems that perfectly match client needs, regardless of whether we are installing new facilities, replacing obsolete facilities, or implementing power-saving measures. We propose optimal solutions that best meet clients' budgets and needs using equipment from diverse manufacturers.

When refurbishing facilities, we can propose segmenting or minimizing construction periods to provide flexible operation plans.

- Key Points

-

- We select optimal equipment from diverse manufacturers, prioritizing clients' needs.

- We propose segmenting or minimizing construction periods, considering the downtime.

- Major Projects Completed

-

- Ultrahigh-voltage receiving and transforming facilities for an electric wire manufacturer [Shizuoka]

Electrical Systems for Large Plants

Extensive experience with electrical facilities for ironworks and other large plants

We offer EPCC services for the installation of electrical facilities at large plants such as steel and non-ferrous metal plants and paper mills both in Japan and abroad. We can also procure and install electrical products from overseas manufacturers.

Major Plants

Steel and non-ferrous metal plants: Hot rolling, cold rolling, shaped steel, bar steel, wire rod, electrical furnace, continuous casting, and other processes

Paper manufacturing plants: Paper machines, winders, etc.

Main equipment

Power receiving and transforming facilities, motors, control panels, air conditioning, etc.

- Key Points

-

- We support electrical equipment from overseas manufacturers.

- Major Projects Completed

-

- Hot strip mill of a steel company

Cleanrooms

Designing and constructing cleanrooms optimized for their intended use, drawing on reliable engineering expertise and extensive experience

Precision equipment, pharmaceutical, and food manufacturers require cleanrooms with different configurations and performance classes according to their purposes. There are cleanroom standards for different classes.

In addition to the maintenance of cleanliness, cleanrooms require different technologies and knowledge in order to cope with and prevent contaminants.

We offer a suite of services for the construction of cleanrooms tailored to client requirements, encompassing proposals, design, equipment procurement, installation, and validation. We employ air-stream analysis and other latest technologies, drawing on our wide-ranging experience and track record.

- Key Points

-

- We offer one-stop services for design, procurement, installation, and validation for purpose-built cleanrooms.

- Major Projects Completed

-

- Pharmaceutical raw material storage [Tokyo]

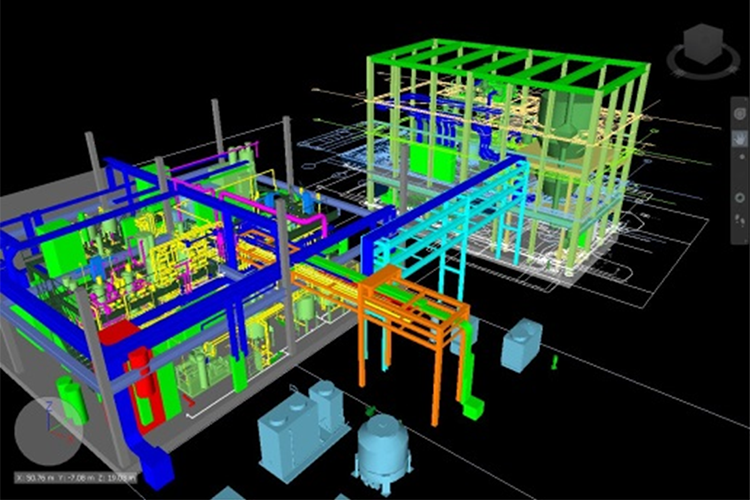

Reverse Engineering

Control equipment from overseas manufacturers upgraded through reverse engineering according to Japanese specifications

Our reverse engineering technology allows us to restore aging control facilities. The equipment that has been reliably used to date by clients can be retrofitted. Feel free to consult with us in the following situations:

- When you wish to upgrade control equipment from overseas manufacturers according to a Japanese specification

- When you wish to replace your analog control panels with programmable logic controllers (PLCs)

- When you wish to replace control equipment that is currently a black box

- When you wish to replace DC motors with AC motors

-

*

Reverse engineering is a process of analyzing the output of existing control facilities to realize the same function in a new manner.

- Key Points

-

- Drawing on our unique expertise, we examine and analyze existing functions to reproduce the same functions in a new manner.

- We also support black boxes.

- We offer these services for a wide range of equipment from Japanese and overseas manufacturers.

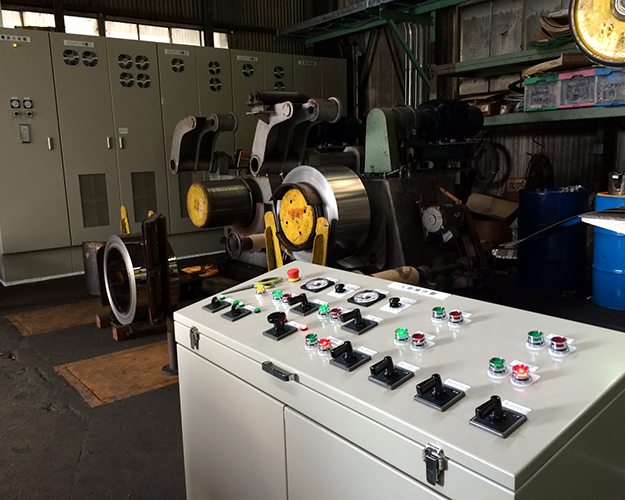

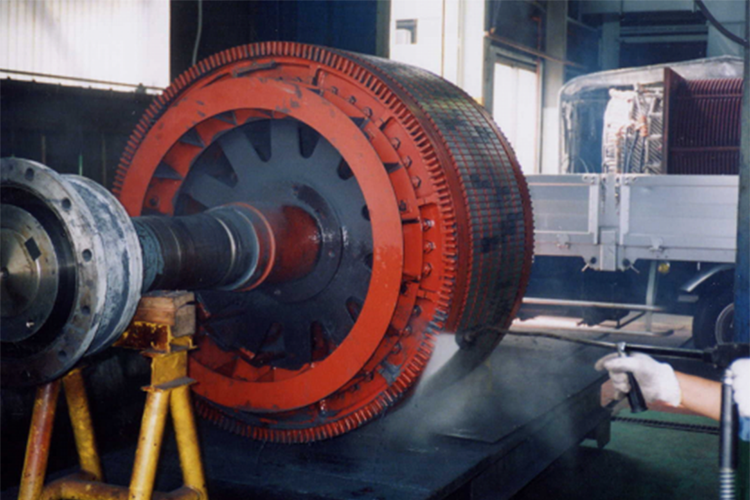

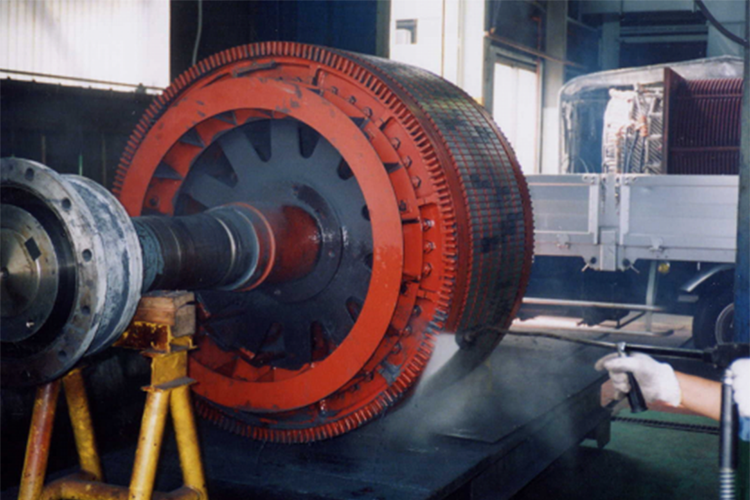

Motor Maintenance Service

Maintenance and refurbishment services for equipment of all brands

Maintenance and refurbishment services for equipment of all brands, including high-voltage motor insulation diagnosis

At the time of inspection, we offer proposals for long-term maintenance plans in addition to high-voltage motor insulation diagnoses and on-site vibration measurements.

Regarding refurbishment, we offer an array of services, ranging from the dismantling of equipment to transportation, diagnosis, factory repair, inspection, installation, and on-site commissioning.

Main Equipment

Induction motors, DC motors, special motors, synchronous motors, geared motors

Main maintenance

Mechanical repair, high-voltage motor insulation analysis, coil repair and rewinding, balance adjustment, coil insulation analysis

- Key Points

-

- An array of services, ranging from the dismantling of equipment to transportation, diagnosis, factory repair, inspection, installation, and on-site commissioning

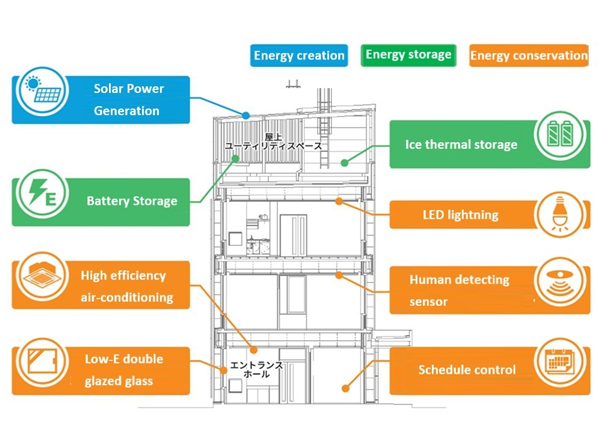

Achieving Carbon Neutrality through ZEB

We have set a target for ZEB to account for more than 50% of the design work we perform in FY 2025

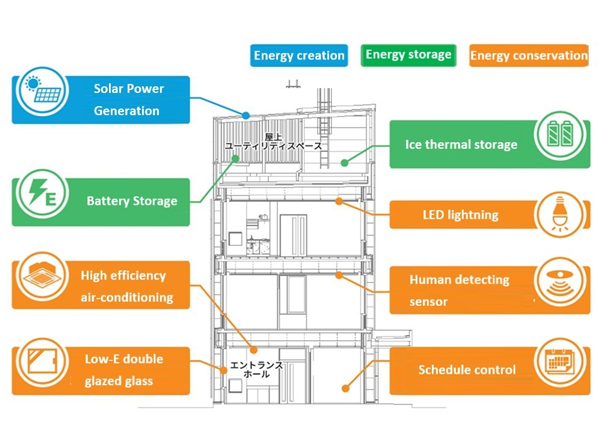

- The energy map for ZEB in the office building is used to achieve high efficiency and reduce utility costs for the entire building.

-

- Energy creation(Solar Power Generation)

- Energy storage(Storage Battery, Ice thermal storage)

- Energy conservation(LED lightning, High efficiency air-conditioning, Human detecting sensor, Low-E double glazed glass, Schedule control)

●What is "ZEB"?

It stands for "Net Zero Energy Building" (ZEB) .It is a type of building that designed to achive a confortable environment while reducing the annual primary energy balance consumption in the building to zero.

Ministry of the Environment " ZEB PORTAL"https://www.env.go.jp/earth/zeb/about/index.html