Gas Engine Power Generation

EPCC Services for Gas Engine (Cogeneration) Power Plants

Gas Engine (Cogeneration) Power Generation

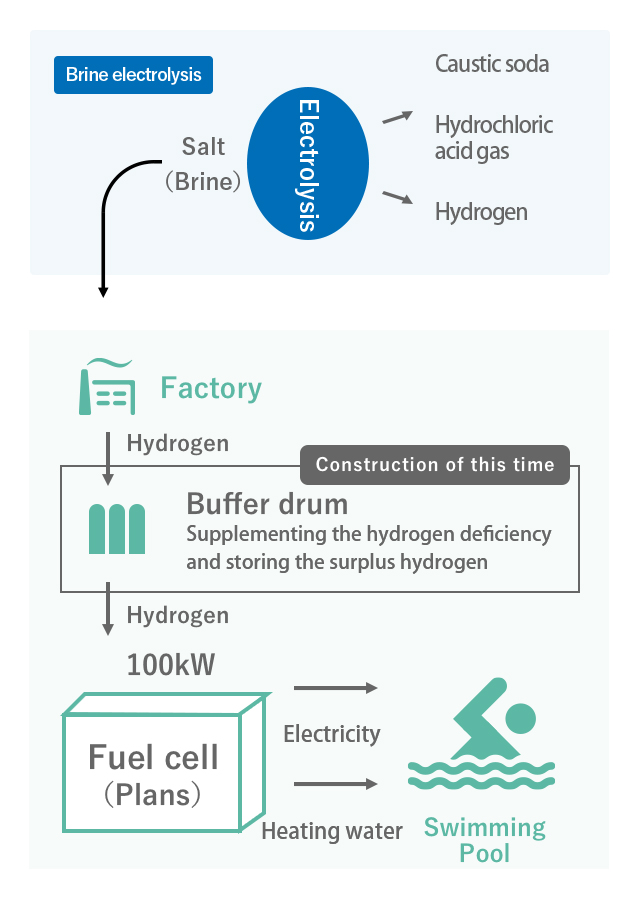

We offer EPCC services for gas engine (cogeneration) power plants, ranging from building construction to auxiliary equipment. Cogeneration using natural gas or other sources of energy is an effective means of distributed generation of electricity that recovers exhaust heat from generators. The recovered heat can be reused to heat and air-condition factories and to heat and cool water with water heaters or refrigerators.

We deliver the benefits of cogeneration gas engines, drawing on our proven engineering expertise.

Cogeneration gas engine generators are tailored to specific usage conditions and environments as proven in the extreme cold of Hokkaido.

- Key Points

-

- We select equipment from many manufacturers according to client requirements.

- We offer proposals for effective utilization of exhaust heat.

- Major Projects Completed

Liquid Biomass Power Generation

Renewable energy help clients fulfill corporate social responsibility (CSR) by balancing out CO2 levels.

Liquid biomass power generators run a diesel engine with liquid fuel such as palm oil. Liquid biomass generation is a new and attractive source of renewable energy qualified for feed-in-tariff (FIT) incentives.

Liquid biomass power generation provides more stable output than solar photovoltaic and wind power generation. In addition, liquid biomass power generation is a carbon-neutral energy source that has no adverse effect on the atmospheric CO2 density and therefore contributes to the conservation of the global environment.

We offer EPCC services for constructing power plants, including oil storage tanks.

- Key Points

-

- More stable source of electricity than solar photovoltaic and wind power generators

- Carbon-neutral energy source, contributing greatly to the fulfillment of CSR

Wooden Biomass Power Generation

A new form of energy that integrates the power generation business and the forest industry, contributing to revitalization of local communities

Wooden biomass power generation is a new form of energy source that uses forest scraps and factory scrap wood as fuel.

The key to successful wooden biomass power generation lies in a stable fuel supply and high-performance boiler systems that ensure stable operation.

We have established connections with prominent timber suppliers and proven boiler manufacturers to offer proposals for one-stop services, ranging from wood procurement to power plant construction.

It is expected that you can ensure stable operation of a 2-MW-class power generator if you can procure wood from within 50 km. This will promote the consumption of locally produced materials and contributes to the revitalization of the local forest industry.

- Key Points

-

- 2-MW-class biomass power plants qualified for the FIT incentives are the main target of our proposals.

- You can create greater value by coexisting with the local forest industry.

- Major Projects Completed

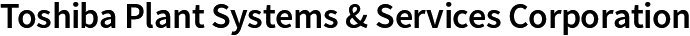

Hydrogen Energy Power Generation

Contributing to all processes of power generation, ranging from the production of fuel from hydrogen to the transportation and storage of hydrogen

Hydrogen energy generation, which helps reduce the environmental burden, is a superior source of fuel that is extensively being researched and utilized. As part of our on-going initiative for the hydrogen energy generation business, we are currently carrying out a project for efficiently using gby-product hydrogenh generated by chemical plants. We are now installing pipes and tanks to deliver hydrogen gas from chemical plants.

We are also participating in the hydrogen projects being undertaken by Toshiba (using solar energy to produce hydrogen and generating electricity with fuel cells using the hydrogen produced). We are in charge of manufacturing and installing the equipment.

- Key Points

-

- We offer diverse engineering methods, targeting hydrogen generation, including drum buffer technology for storing hydrogen just before fuel cells.

- Major Projects Completed

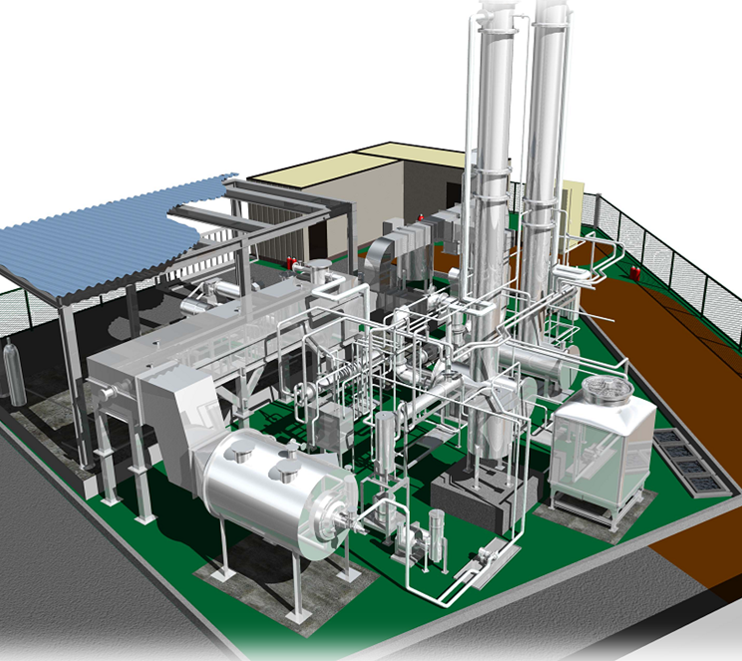

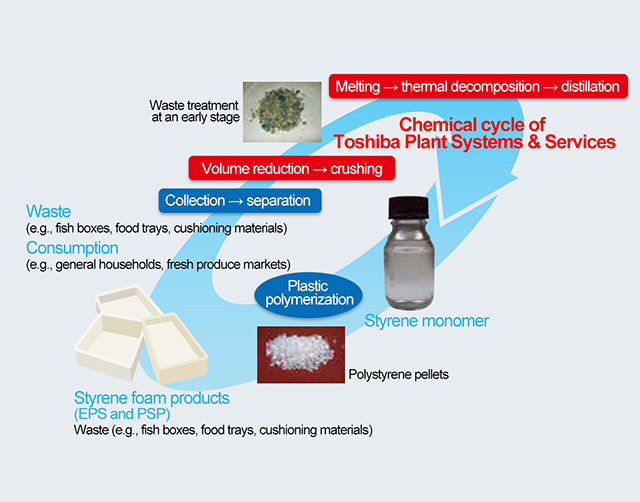

Recycling plant into Styrene monomers

Solving plastic waste issues

Styrene monomers are basic chemical compounds produced from petroleum. They are transparent organic solvents that are used as materials to produce polystyrene, synthetic rubber, and other plastics.

Toshiba Plant Systems & Services uses its proprietary technology to recycle styrene foam waste into styrene monomers, which are circulative resources. This process emits less carbon dioxide (CO2) than producing styrene monomers from petroleum.

Recycled styrene monomers are of high quality. Since the recovery rate of styrene foam is high, its recycling can be a profitable business.

- Key Points

-

- Compliant with JIS and ASTM quality standards

- More than 60% recovery rate

- Requires no external fuel (Recycling plants run only on the fuel oil produced as a by-product.)

- Emits less CO2 than producing styrene monomers from petroleum

* Toshiba Plant Systems & Services has constructed a demonstration plant using a subsidy from the New Energy and Industrial Technology Development Organization (NEDO) and evaluated its performance.