The causes of rapid growth of Toshiba Plant Systems & Services lie in the cultivation of total engineering systems, investment in human resources, and Balanced Critical-to-Quality Management (BCM), or strategic business management based on balanced scorecards.

We expect to enjoy further growth through the promotion of our three major policies: 1) developing a business model that delivers high profitability and growth; 2) promoting innovation; and 3) implementing CSR management.

We have grown owing to our ceaseless effort aimed at business expansion, technological enhancement and process reform.

People, society, technology, and demand change over time, but the core always remains the same.

Society changes sometimes slowly and sometimes rapidly with the times and the technology, but our long-term vision that navigates our business has helped us grow steadily without losing sight of our core essence. We stay firm and grounded in forging a path into the future.

"People" are our primary asset.

Our driving force comes from field sites where people gather.

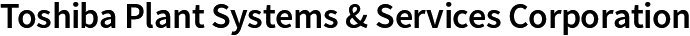

Field Site × People Power

Providing Japanese quality throughout the world

People with highly developed technical skills and expert knowledge gather at field sites.

Hundreds and thousands of people are involved in projects from start to finish.

By utilizing their potential and holding mutual respect, we are able to complete large projects.

We at Toshiba Plant Systems & Services value personnel who have knowledge, passion, and communication skills to exercise leadership at field sites. People are our primary asset that provides the strength for sustained growth.

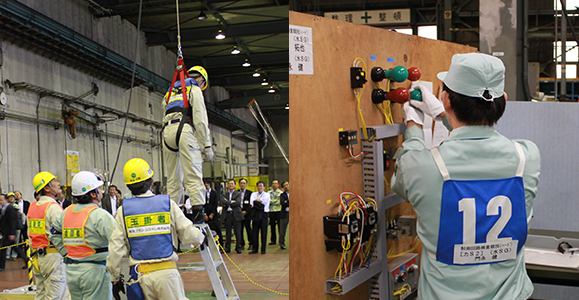

Security, Safety, and Quality

High-quality services prioritizing safety and security

On-site safety is crucial for maintaining the quality of a plant. Only when safety is ensured can people work to their full potential. In addition, on-site safety and sustained quality help us protect our clients' social credibility. Toshiba Plant Systems & Services has achieved zero accidents and zero quality nonconformities at many sites.

Security, safety, and quality constitute the essence of our strength.